Made in Greece - CE 2006/42 EC Machinery Directive

Our innovative Kataifi Master™ machine line is designed for the production and baking of kataifi. It operates by maintaining a continuous flow of kataifi dough through a metal conveyor within a baking tunnel. This tunnel is heated to 180°C using 16 burners that run on either natural gas or LPG. The kataifi requires a baking time of approximately 4-8 seconds within the tunnel. After exiting, the product is gathered and packaged.

The production capacity ranges from 200 kg/h to 500 kg/h, varying according to the moisture content of the final product and the fuel’s calorific value.

Kataifi Master™ Engine parts

The automatic kataifi production line, classified as industrial machinery, comprises the following components:

1. Mixing agitators

2. Shelley

3. Baking tunnel

4. Quantities splitting cradle

5. Product collection conveyor belt

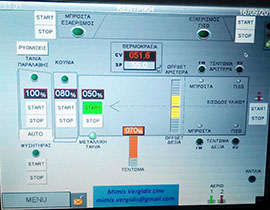

6. Production line control panel

7. Individual drive elements (motor, drive chain, pre-tensioning system with bolt and retaining spring)

The performance and design of the Kunafa machine demonstrate our meticulous attention to detail. Our Kataifi maker, a product of careful planning and design, is straightforward and dependable, offering the customer a machine that excels in performance, durability, and ease of use, with no maintenance required. It integrates seamlessly and efficiently with your existing recipes, ensuring the production of top-quality kataifi without the need for any adjustments to your professional techniques.

Combined with our exclusive Kunafa Carpet Module, enables limitless possibilities for the creation of traditional Arab sweets and savoury products.

| Technical specifications | Economy | Basic | Premium |

| Production Capacity | 120-150 kg/h | 250-300 kg/h | 350-500 kg/h |

| Width | 1500 mm | 2000 mm | 2000 mm |

| Height | 2500 mm | 2500 mm | 2500 mm |

| Length | 7000 mm | 10000 mm | 13000 mm |

| Components | Steel & Stainless Steel | Steel & Stainless Steel | Steel & Stainless Steel |

| Built in Laser reader* | YES | YES | YES |

| Electricity Consumption | 5-7 kw/h | 5-7 kw/h | 8 kw/h |

| Gas Consumption | 15 | 26 | 32 |

| Mixers | 2 x 600 kg | 3 x 600 kg | 4 x 600 kg |

| Conveyor Belt | 4000 mm | 4000 mm | 4000 mm |

*Displays and regulates temperature, size and product weight.

Kataifi Machine reserves the right to modify technical specifications without prior notice due to ongoing technical advancements.

Competitive Advantage |

Standard Market Kataifi Machine |

Automatic Linear Kataifi Machine |

| Size | Diameter: 3000 mm

Height: 2500 mm |

Length: 10000 mm

Height: 2500 mm Width: 2000 mm |

| Production Capacity | 50-65 kg/h | 250-400 kg/h |

| Space | 9 m x 9 m = 81 m x 5 machines = 405 m² | 24 m x 6 m = 144m² |

| Length | 7000 mm | 10000 mm |

| Mixers | 10 | 3 |

| Built in Laser reader* | NO | YES |

| Staff | 8-10 workers** | 3 workers plus 1 specialist |

| Product Quality | ** | ***** |

|

|

|

| Energy | Electricity consumption: 2kw/h x 5

Gas consumption: 10 QL/h x 5 |

Electricity consumption: 7kw/h

Gas consumption: 26 QL/h |

| Workplace Temperature | 5 MACHINES: + 30 – 35°c (405m²) | 1 MACHINE: 12 – 16°c (144m²) |

| Downtimes | Necessity of pausing production

after the first 12 h, for 4 h |

Necessity of pausing production

after the first 18 h, for 4 h |

|

|

|

*Displays and regulates temperature, size and product weight.

**4-5 of them must be specialists.

Due the technical progress, Kataifi Machine reserves the right to change technical features without notice.

Notes:

Our Kataifi Machine is the only machine in the market which adjusts DIGITALLY the exact weight of the final product (for example you can choose from the digital control panel your desired product choice of 450 g/per pack )

You can also digitally control the width and length of the final product for packaging purposes. Product thickness is regulated with the pressure of the nozzles. It is digitally controlled in order to stabilise the flow of the dough. (The diameter of the nozzles is configurable).

By controlling / changing speed and pressure together, the flow of the dough is accurately regulated.

Regarding temperature adjustment: the thickness of the metallic belt is only 1,2 mm and compared to the 5-6 mm of the old circular machine, the time balance has greater efficiency. If we have smaller nozzles and high temperatures, we increase the pressure at the nozzles together with speed in order to reduce the baking time, to avoid making the product fragile.

When we have low temperatures, we reduce the pressure at the nozzles as well as the belt speed, to increase the length of baking, in order not to flatten the product. The baked dough separates from the hot surface by itself since it reaches the peak time of baking.

Technical characteristics

Specifications

Operating voltage: 3 PHASE 400 V

Frequency: 50 Hz

Electric voltage: 230V / 400V

Machine weight: 3tn

Operating temperature: Up to 200⁰C

Productivity: 200-400kg / h

Total drive power: 5,2kw

Total thermal power: 350kw

Gas Emission Pressure: > 800mbar

Number of burners: 22

Burner operating pressure: 200mbar

- After thoroughly examining that all three mixers are clean from dough remnants, wash them out with water and leave open the cap located at the bottom of mixer A.

- Drain mixer A from water and close the cap. Proceed in measuring the quantity of water to be used according to the selected recipe (e.g., 275 kilos of water at the required temperature of 8-14 Celsius).

- Start mixer A at the rotational speed of 30 rpm (rounds/minute). Gradually add 100 kilos of flour into the mixer over the time span of 10 minutes.

- Increase the rotational speed of mixer A to 40 rpm. Afterwards, add the recipe’s additional dry ingredients (e.g., salt, potassium sorbate, amyl). Next, gradually add 100 kilos of flour over the time span of 12 minutes.

- Increase the rotational speed of the mixer to 60 rpm and gradually place 50 kilos of flour within the time span of 5 minutes. Subsequently, add the fatty oils of the recipe to mixer A (e.g., soya lecithin, sunflower oil).

- Amplify the rotational speed of mixer A to 75 rpm. Next, add 5 kilos of water and leave the mixer in operation for 13 minutes. Gradually reduce mixer A’s rotational speed to 0 rpm while simultaneously bringing the churn dasher to a horizontal position. Make sure mixer A is completely turned off. Take the cleaning stick and scrape clean the mixer’s interior, as well as the churn dasher. Use the remainder of the water mentioned in the selected recipe to wash away remnants along the mixer walls.

- Consecutively, turn on mixer A and gradually increase the rotational speed to 85 rpm, and allow the mixer to operate for an hour and thirty minutes. Fifty minutes after mixer A has been in operation, repeat the above-mentioned procedure (steps 1-7) for mixer B. Similarly, fifty minutes after mixer B has been in operation repeat steps 1-7 for mixer C.

Note: Immediately after completing steps 1-7 for the respective mixers, thoroughly clean each mixer and its compartments to ensure the continual operation of the machine.

- Reduce the rotational speed of mixer A at 40 rpm and leave it in operation for 75 minutes.

- Once 75 minutes have passed, turn off the mixer. After pausing the mixer for 15 minutes the dough-batter is ready to be filtered into a smaller container and drained through the dough-batter separator. The aforementioned procedure describes the kneading process. It is imperative to note that the time of kneading and quantity of water utilised depend on the quality of the flour employed in each use.

Dimensions of the machine : 2 m Width X 10 m Length X 2.50 m Height Plus 4m Product Conveyor Belt and 6 /600 kg Capacity Mixers

Equipped with Laser Readers controlling: Temperature Dimension & Weight of the final product.

Electricity consumption: 7 kw /hour

Gas consumption: 25 litres /hour

Production capacity: from 200 to 400 kg /hour

Maximum Dimensions: 13500 mm Length, 2100 mm Width, 2700 mm Height